Trenchless Pipe Repair & Replacement

When your sewer line is failing or worn out, Allied Plumbing & Trenchless delivers fast, minimally invasive solutions. Our trenchless technology restores your line without destroying your yard, driveway, or landscaping. With advanced inspection tools and trenchless repair methods, we diagnose issues accurately and complete repairs or full line replacements—with far less disruption, mess, and cost than traditional excavation.

With more than 15 years of trenchless experience, we’re one of the region’s most trusted specialists. Proudly serving the Pacific Northwest since 2009, our team is fully licensed, insured, and NASSCO Certified—one of the few local companies with this qualification. Homeowners and businesses rely on us for reliable workmanship, honest communication, and long-lasting results.

We stand behind every project we complete and take pride in being the team you can count on to do the job right the first time. Don’t just take our word for it—see what our customers have to say!

Get your sewer system back on track with our licensed plumbing professionals. Contact us at (509) 461-2393 or online for a FREE site evaluation!

Why Choose Trenchless Over Digging?

Traditional sewer and water line repairs often require trenches, heavy equipment, and costly property damage. Trenchless technology eliminates that hassle by repairing or replacing lines through small access points—saving time, money, and mess. With durable materials and advanced methods, trenchless solutions protect your property and provide reliable performance for decades.

Key Benefits of Trenchless Repair & Replacement

- Less Intrusive & Property-Friendly - Trenchless methods require only one or two entry points, eliminating the need for extensive excavation. Your landscaping, driveways, patios, and hardscapes remain intact.

- Time & Cost Savings - Repairs are completed significantly faster—often in days instead of weeks. This reduces labor costs and minimizes disruption to your home or business.

- Cost-Effective Long-Term - Avoid the high expense of restoring lawns, hardscaping, flooring, and walls. Trenchless repairs typically cost less overall because they eliminate restoration after the job.

- Durable, Long-Lasting Solutions - Modern trenchless materials—such as high-strength pipe and epoxy liners—can last 50+ years. These solutions resist corrosion, root intrusion, and leaks.

- Ideal for Difficult or Sensitive Areas - Perfect for lines located under homes, driveways, patios, landscaping, or other areas where digging would be destructive or impossible.

- Environmentally Friendly - Trenchless methods reduce soil disturbance, waste, and environmental impact compared to traditional excavation.

Cured-In-Place Piping

Cured-in-place pipe lining (CIPP) is one of the most advanced and effective trenchless sewer repair techniques available. After thoroughly cleaning the existing pipe, we insert a flexible, epoxy-saturated liner into the damaged section. Once in place, the liner is inflated to press tightly against the inside of the pipe. It is then cured using heat or ultraviolet (UV) light, allowing it to dry and harden in place.

The result is a smooth, seamless interior surface that restores your line to near-new condition—improving flow, sealing leaks, and adding decades of structural life without digging up your yard or driveway.

CIPP is ideal for repairing:

- Sewer line leaks and infiltration

- Cracked or fractured pipes

- Tree root intrusion

- Heavy corrosion or deterioration

- Aging clay, cast iron, ABS, or concrete lines

Because CIPP requires only one or two small access points, it provides a fast, cost-effective, and minimally invasive alternative to excavation, offering long-lasting performance and reliable protection for your sewer system.

Pipe Bursting (Trenchless Pipe Replacement)

Pipe bursting is a trenchless method used when a sewer or water line is too damaged, collapsed, or corroded for CIPP lining to be effective. With this technique, a specialized bursting head is pulled through the existing pipe, breaking apart the old line while simultaneously pulling a brand-new HDPE pipe into its place. This allows for full pipe replacement without digging a trench or disturbing your yard, driveway, or landscaping.

Pipe bursting is ideal for lines that are:

- Severely deteriorated or collapsed

- Too warped or misaligned to support a liner

- Affected by extensive root intrusion

- Undersized and needs to be upsized for better flow

This method is more involved than CIPP but provides a long-lasting, highly durable solution, even for pipes that have rotted away or completely failed. Because the new pipe is seamless and corrosion-resistant, it delivers decades of reliable performance without the mess of traditional excavation.

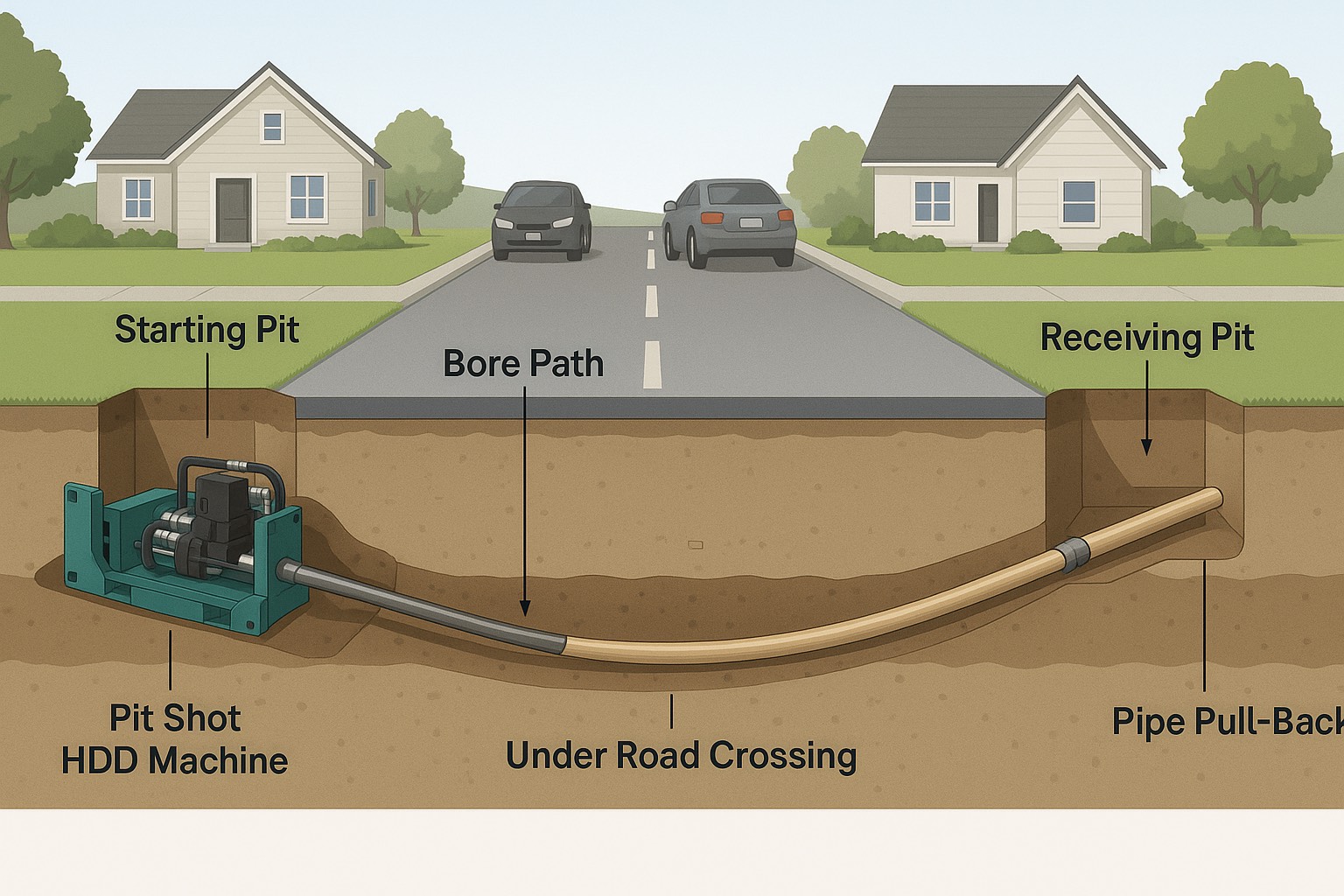

Directional Drilling (Horizontal Directional Drilling – HDD)

Horizontal directional drilling (HDD) is a trenchless installation method that allows us to run new water lines, conduit, and utilities without digging trenches across your property. Instead of tearing up driveways, landscaping, or hardscapes, a specialized drill creates a controlled underground path, and the new line is pulled through to create a seamless, long-lasting installation.

Using advanced tracking technology, our technicians monitor the drill head throughout the process to ensure the bore follows the precise planned path. Once the pilot hole is created, it can be enlarged as needed and fitted with durable, seamless piping that offers exceptional performance and longevity.

Directional drilling is ideal for:

- Installing new water service lines

- Replacing aging or poorly performing water lines

- Running conduit for electrical, fiber, or communications

- Connecting properties from septic to city sewer/water utilities

- Installing utilities under driveways, roads, patios, and landscaped areas

Advantages of horizontal directional drilling include:

- Faster installation – No open trenches means quicker project completion.

- Lower costs – Smaller crews and reduced heavy equipment lower overall project expenses.

- Improved site access – Allows installation in areas where open trenching is difficult, unsafe, or would cause significant property disruption.

- Reduced soil disturbance – Seamless piping and minimal surface impact help prevent soil contamination.

- Environmentally friendly – Preserves landscaping, reduces excavation waste, and minimizes disruption to the surrounding area.

Ready to learn whether directional drilling is the right solution for your project?

Schedule your FREE site evaluation today, and our experienced team will assess your property and provide clear, honest guidance on the best trenchless options for your needs.

Epoxy Coating

Epoxy coating is a trenchless pipe rehabilitation method that restores aging or corroded pipes by applying a durable epoxy resin barrier to the interior surface. This process seals minor leaks, prevents further corrosion, improves flow, and extends the life of the piping system—all without excavation or tearing into walls, floors, or landscaping. Epoxy coating works best for pipes that are still structurally sound but are experiencing internal deterioration.

How Epoxy Coating Works

- Inspection - A CCTV sewer or pipe camera is used to examine the interior condition of the pipe, identify problem areas, and confirm whether epoxy coating is an appropriate solution.

- Cleaning - Mechanical cleaning tools—such as rotary heads, cable machines, or high-pressure water jetting—remove corrosion, scale, buildup, and debris to ensure proper adhesion. The pipe is then thoroughly dried so the epoxy bonds correctly.

- Epoxy Application - A liquid epoxy resin is sprayed, brushed, or air-blown onto the interior pipe walls. Multiple coats may be applied to achieve the proper thickness and complete coverage.

- Curing - The epoxy cures (hardens), forming a smooth, seamless, corrosion-resistant barrier that functions as a protective “pipe within a pipe.”

Ideal Uses for Epoxy Coating

Epoxy coating is best suited for pipes that have internal damage but remain structurally intact. It is commonly used to address:

- Corrosion and rust in metal pipes (cast iron, steel, copper)

- Pinhole leaks and minor gaps in potable water lines

- Recurring blockages or low flow caused by internal buildup

- Piping in hard-to-reach areas where excavation is disruptive (walls, ceilings, foundations, vertical stacks)

Limitations

Epoxy coating is not suitable for pipes that are:

- Collapsed

- Severely deformed

- Missing sections

- Experiencing major structural failure

For those situations, structural trenchless methods like CIPP lining or pipe bursting are the better choice.

Wondering if Epoxy Coating Is the Right Solution for Your System?

Schedule your FREE site evaluation, and our specialists will inspect your piping, review your options, and provide honest recommendations tailored to your property.